What Is Paraffin Wax Specification?

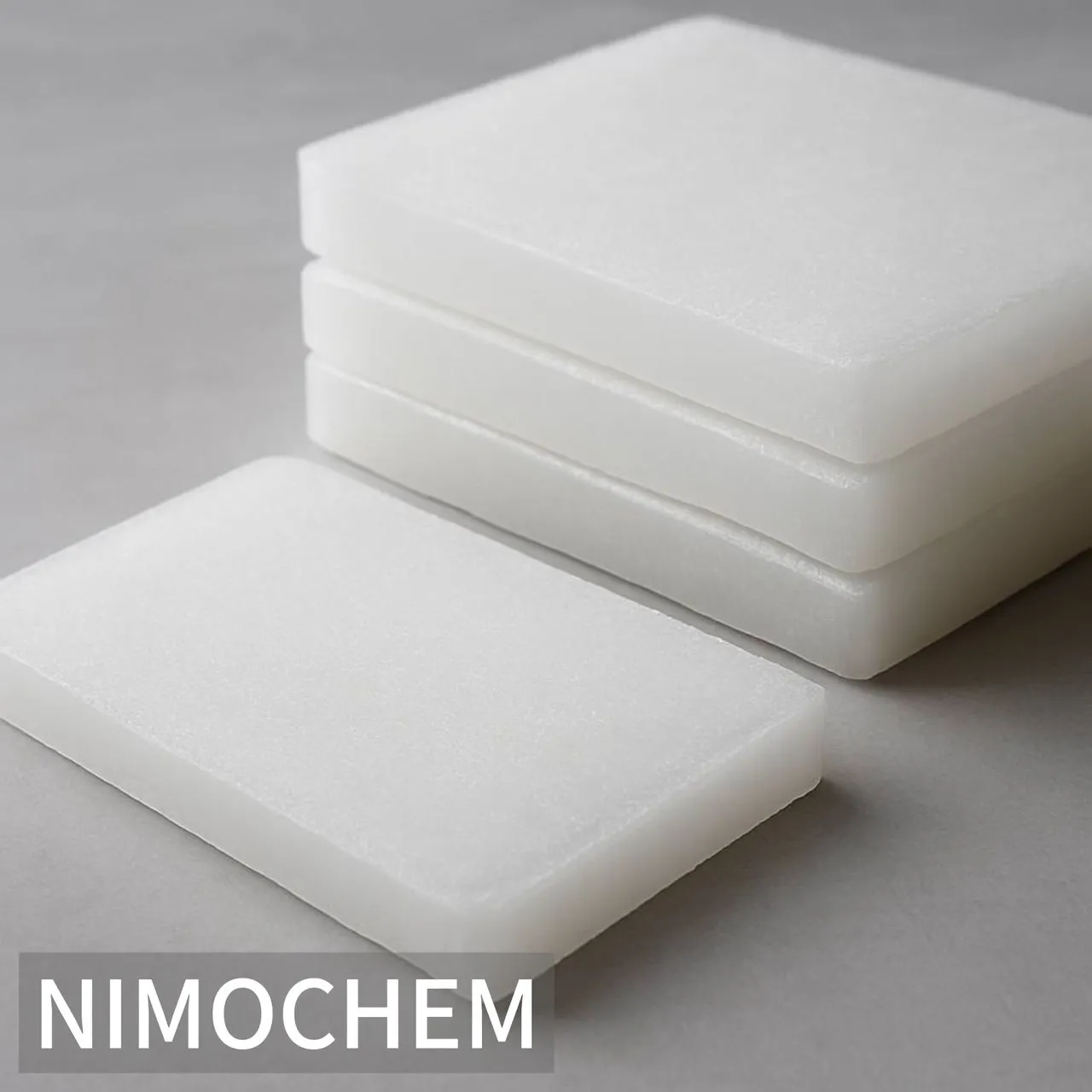

Paraffin wax specification is a detailed list of physical and chemical properties. These properties define the quality and use of paraffin wax products.

As a leading supplier of paraffinic products at Nimochem We know that clear specifications help buyers pick the right grade for their needs. This applies to candles, cosmetics, packaging, and industrial coatings.

Typical specifications include oil content, melting point, color, hardness, and odor. These factors influence performance, safety, and regulatory compliance, especially in sectors like pharmaceuticals and food packaging.

Why Paraffin Wax Specification Matters in Industrial Applications

Industrial buyers rely on paraffin wax specification data to ensure product consistency and compatibility with their production lines. For example, the melting point of paraffin wax plays a key role in molding, dipping, and coating applications. A mismatch in this spec could lead to quality defects or equipment issues.

Moreover, applications such as candle manufacturing or cosmetic formulation require paraffin wax that meets strict standards. A deviation in oil content or color can affect burning quality, texture, and even customer satisfaction. That’s why sourcing from a reliable supplier like Nimochem ensures peace of mind and quality assurance.

Understanding Paraffin Wax Grades and Their Specifications

Paraffin wax is generally divided into fully refined, semi-refined, and slack wax grades. Each has its own set of specifications depending on the intended use. Fully refined paraffin wax usually has low oil content, around 0.5% or less. It is used in areas that need high purity, like cosmetics, pharmaceuticals, and food packaging.

Oil Content in Paraffin Wax Specification

Oil content directly affects the hardness, appearance, and thermal behavior of paraffin wax. For example:

• Fully refined wax: ≤0.5% oil

• Semi-refined wax: 0.5–1.5% oil

• Slack wax: >3% oil

A lower oil content results in a harder, cleaner-burning wax, ideal for candles or skin-contact applications.

Melting Point Range in Paraffin Wax Specification

The melting point of paraffin wax typically ranges between 46°C to 68°C depending on the grade and intended use. Industries dealing with molding, dipping, or coating processes often require narrow melting point tolerances for precision.

• Low melting point (46–52°C): Cosmetic and therapeutic use

• Mid-range (52–60°C): General-purpose candles

• High melting point (60–68°C): Industrial and packaging use

At Nimochem, we supply various melting point grades customized for your needs.

Color and Appearance in Paraffin Wax Specification

Color is more than just a visual factor—it indicates purity. Paraffin wax is often rated using Saybolt color scale or visual inspection. High-quality wax appears white, translucent, and odorless. Discoloration can signal contamination or high oil content, which affects product aesthetics and functionality.

We ensure our paraffin wax meets premium appearance standards, especially for cosmetic and pharmaceutical use.

Paraffin Wax Specification vs Microcrystalline Wax

While both are petroleum-based, paraffin wax and microcrystalline wax have different structures and specs. Paraffin wax is more crystalline and has a sharper melting point, while microcrystalline wax is stickier, more flexible, and melts gradually. As a result, microcrystalline wax is preferred for adhesives and barrier coatings, whereas paraffin wax is better for candles, packaging, and skincare.

Final Thoughts

If you’re sourcing paraffin wax for your business, reviewing and understanding paraffin wax specification is critical. At Nimochem, we provide detailed technical datasheets and consistent quality so you can focus on growing your business with confidence.

Get in touch with us today to request a sample or full specification sheet tailored to your industry.