Industrial Giants: Paraffin Wax and Liquid Paraffin are Staples in Manufacturing

There are just some materials in manufacturing that work behind the scenes to make common products more effective and last longer. Two such products, paraffin wax and liquid paraffin, are two integral materials found in everything from packaging to cosmetics. While both have different properties, they do share one thing: their capability to enhance production. Let’s see how these two giants are in wide usage across industries, along with the reason behind their vital usage.

1. Paraffin Wax: Main Agent in Coating and Waterproofing

Paraffin wax is a by-product from petroleum materials, and for this reason it is used in manufacturing because of its water-repelling nature, smooth finish, and protection against the elements. It is also appreciated because of its hydrophobic nature, making the material indispensable where the resistance to moisture is required.

a. Hero of Packaging Industry

In the packaging industry, paraffin wax is a film star, coating cardboard and paper materials. The wax forms a sort of barrier that preserves packaged goods by preventing moisture from reaching the products either during transport or storage. You have probably seen this where foodstuffs like fruits and vegetables, or even baked goods that are prone to absorbing moisture, are stored in paraffin-coated packaging.

b. Textiles: Water-Resistant Fabrics

In textiles, paraffin wax is applied to fabrics to make them water-resistant-for example, a raincoat or a tent you use on a camping trip. These products have most likely been treated with paraffin wax to apply the waterproofing that it needs to endure harsh weather conditions.

c. Candle and Crayon Production

Paraffin wax is an ingredient in candles and crayons; it is the main constituent of those items. Because of its ease of molding and color-holding properties, it’s best for decorative candles in all manners of vibrant colors, while with crayons, they depend on the wax’s ability to hold form and are still easy with which to work.

Read about uses of paraffin wax!

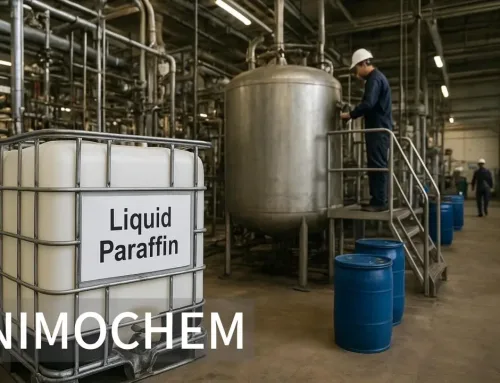

2. Liquid Paraffin: A Lubricant and Emollient Workhorse

Liquid paraffin is derived from petroleum, like the former, but it plays a very contrasting yet equally important function in the production process. Commonly known for its lubricating and emollient properties, it becomes very vital in industries ranging from cosmetics to pharmaceutical industries, even in machinery.

a. Cosmetics Industry Staple

In the cosmetic world, liquid paraffin is a major component of moisturizing creams and lotions. It also works as an emollient, which means that it helps soften and hydrate the skin. You find these in products intended for dry or sensitive skin; it works very well in locking out moisture, even creating some sort of protective barrier for smooth skin.

b. Medical and Pharmaceutical Uses

Liquid paraffin is also a commonly used pharmaceutical in such products as laxatives and ointments for skin. Since it may provide an effective protective covering on the skin, it may serve useful purposes in medical applications involving treatment related to burns, bruises, or abrasions. Its intention is to avoid dryness of the skin and to promote healing.

c. Lubrication of Machinery

Industrial applications of liquid paraffin include its utilization as an effective lubricant for machinery. It is utilized for this purpose because it lessens the friction between moving metal parts, hence extending the life of the mechanical systems, making it easy to run them, and reducing wear and tear. This happens to be especially useful for heavy-duty machinery since the effect of heat and continuous motion greatly influences the wear and tear on those parts which are not so treated with lubrication.

3. Where Paraffin Wax and Liquid Paraffin Cooperate

While paraffin wax and liquid paraffin usually serve different purposes, there are instances when these raw materials reveal some overlapping in specific manufacturing applications. One such example is in the packaging industry.

Here, packaging materials could be coated with paraffin wax to protect against moisture, while liquid paraffin acts as a lubricant to make sure the machinery that handles those materials functions well. These two products together enhance efficiency in the manufacturing process while ensuring that the final product meets quality standards.

4. Manufacturing Based on Sustainability

As industries become more ‘green-conscious, there is growing interest in seeking environmentally friendly alternatives to paraffin wax and liquid paraffin, which are by-products of petroleum. Examples of such alternatives that are gaining slow but sure acceptance include waxes that are biodegradable and plant oils emanating from plants. However, considering the previous evidence of dependability and affordable costs of products related to paraffin, these will continue to play an essential part in most manufacturing processes for many years.

Need to know more about paraffin wax and liquid paraffin?

Contact Us ASAP